Mesoline

Sr. Mechanical Systems Engineer

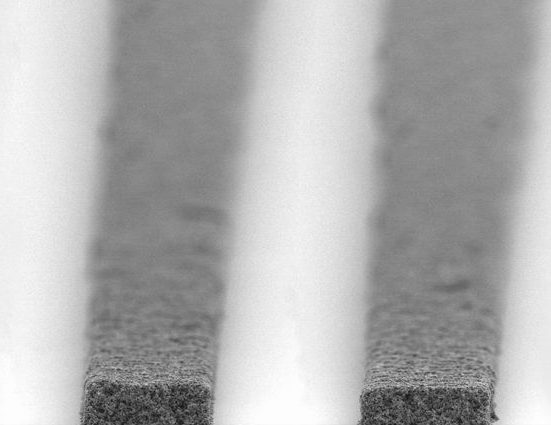

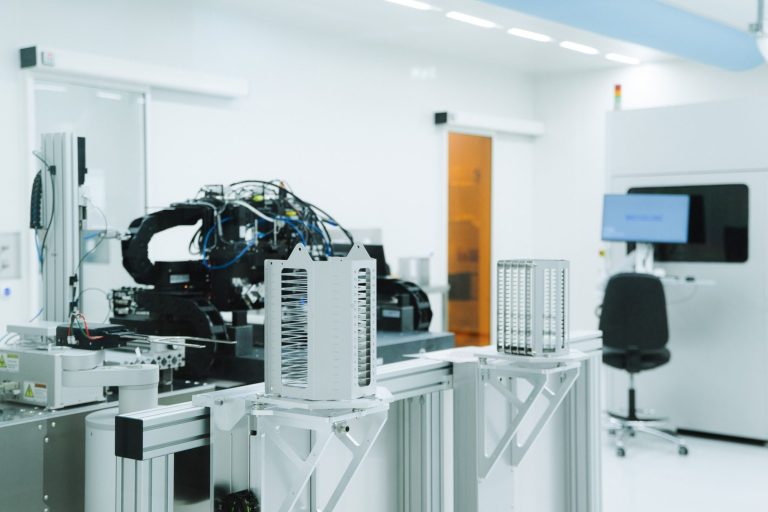

Mesoline is a semiconductor company developing and scaling a novel micro fabrication technology: micro-channel particle deposition (MPD). This novel micro fabrication technology offers ultra-small and reproducible micro features fabricated with extensive parallelization and high scalability. Mesoline is based in Rotterdam and has cleanroom facilities to support clean production and R&D

As a Sr. Mechanical Systems Engineer at Mesoline I am mainly responsible for the design and build of all automated production tools used in Mesoline’s novel MPD (Microchannel Particle Deposition) production. Such as:

- A development platform to demonstrate MPD at wafer-scale. Initially designed to be sold in production.

- Two high volume production platforms to support fully automated high volume production with the in-house developed MPD process.

- A fully automated so-called Bonding tool used in our stamp manufacturing process

- A Laser Sintering System used for localised sintering of printed features.

All designs have a highly modular design which allows for easy upgrading and reduced downtime after module failures/ issues. As these tools are designed according to at least cleanroom class ISO7 requirements. A broad skill set has been demonstrated while designing and building the equipment such as;

- (Mechanical) System Engineering

- Configuration management

- 3D modeling, (Solidworks, NX, Solid Edge)

- Finite Element Analysis (Ansys, SW simulation)

- Design according to SEMI standards.

- Product Drafting for manufacturing.

- Product procurement, (request quoting, price negotiation, ordering)

- Mechanical rework, (machining, turning, milling)

- Clean assembly of modules or systems.

- Testing and validation of modules and systems according to set requirements.

- Rapid prototyping (3D printing; Resin printing, fused deposition printing, metal printing)

- Material Handling Robotics, wafer and stamp handling using Scara Robots and custom made end-effectors, using supplier solutions.

- Mechatronics: motion stage selection, commissioning and operation (single stages, precision XY stages, precision Gantry’s)

- Pneumatics: design, building and testing of 19” Enclosures which provide pneumatic control to process modules.

- Electronics: design, building and testing of 19” Enclosures which provide electronics control to process modules and stage motion control boxes inc. cable feedthroughs and connector/ wiring selection.

- Thermal Control: design and testing of modules with thermal requirements using active cooling and heating solutions.

- Programming: (Python, CodeSys), Small learning programming projects such as data acquisition and processing.

As Mesoline is in the start-up / scale-up phase and has limited personnel, additional responsibilities and tasks are expected such as but not limited to;

- Facilities maintenance & coordination, (clean dry air Compressor & Vacuum Pump selection, monitoring, maintenance planning and troubleshooting)

- Cleanroom coordination (procedures, cleaning services, planned maintenance, gowning, clean air treatment unit troubleshooting)

- General technical support and troubleshooting

Niels Appel

Mechanical Engineer

© Copyright. Alle rechten voorbehouden.

We hebben je toestemming nodig om de vertalingen te laden

Om de inhoud van de website te vertalen gebruiken we een externe dienstverlener, die mogelijk gegevens over je activiteiten verzamelt. Lees het privacybeleid van de dienst en accepteer dit, om de vertalingen te bekijken.