Mesoline

Sr. Mechanical Systems Engineer

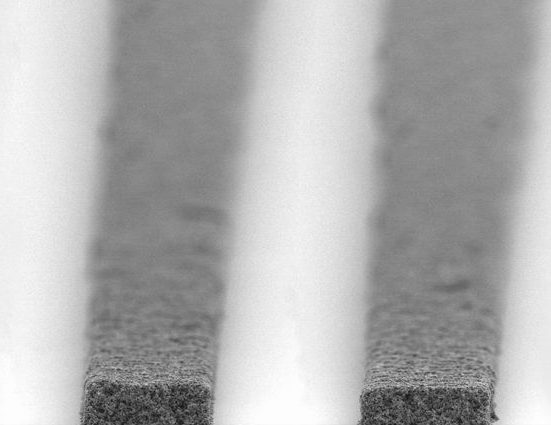

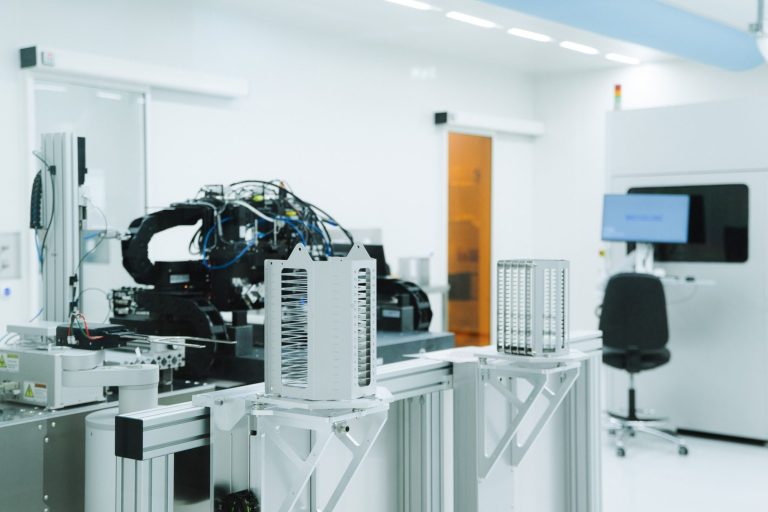

Mesoline is a semiconductor company developing and scaling a novel micro fabrication technology: micro-channel particle deposition (MPD). This novel micro fabrication technology offers ultra-small and reproducible micro features fabricated with extensive parallelization and high scalability. Mesoline is based in Rotterdam and has cleanroom facilities to support clean production and R&D

As a Sr. Mechanical Systems Engineer at Mesoline I am mainly responsible for the design and build of all automated production tools used in Mesoline’s novel MPD (Microchannel Particle Deposition) production. Such as:

- A development platform to demonstrate MPD at wafer-scale. Initially designed to be sold in production.

- Two high volume production platforms to support fully automated high volume production with the in-house developed MPD process.

- A fully automated so-called Bonding tool used in our stamp manufacturing process

- A Laser Sintering System used for localised sintering of printed features.

All designs have a highly modular design which allows for easy upgrading and reduced downtime after module failures/ issues. As these tools are designed according to at least cleanroom class ISO7 requirements. A broad skill set has been demonstrated while designing and building the equipment such as;

- (Mechanical) System Engineering

- Configuration management

- 3D modeling, (Solidworks, NX, Solid Edge)

- Finite Element Analysis (Ansys, SW simulation)

- Design according to SEMI standards.

- Product Drafting for manufacturing.

- Product procurement, (request quoting, price negotiation, ordering)

- Mechanical rework, (machining, turning, milling)

- Clean assembly of modules or systems.

- Testing and validation of modules and systems according to set requirements.

- Rapid prototyping (3D printing; Resin printing, fused deposition printing, metal printing)

- Material Handling Robotics, wafer and stamp handling using Scara Robots and custom made end-effectors, using supplier solutions.

- Mechatronics: motion stage selection, commissioning and operation (single stages, precision XY stages, precision Gantry’s)

- Pneumatics: design, building and testing of 19” Enclosures which provide pneumatic control to process modules.

- Electronics: design, building and testing of 19” Enclosures which provide electronics control to process modules and stage motion control boxes inc. cable feedthroughs and connector/ wiring selection.

- Thermal Control: design and testing of modules with thermal requirements using active cooling and heating solutions.

- Programming: (Python, CodeSys), Small learning programming projects such as data acquisition and processing.

As Mesoline is in the start-up / scale-up phase and has limited personnel, additional responsibilities and tasks are expected such as but not limited to;

- Facilities maintenance & coordination, (clean dry air Compressor & Vacuum Pump selection, monitoring, maintenance planning and troubleshooting)

- Cleanroom coordination (procedures, cleaning services, planned maintenance, gowning, clean air treatment unit troubleshooting)

- General technical support and troubleshooting